There are many advantages to contracting electronic manufacturing services for your business. Most companies are unable do everything in-house, and if they do, they are most likely struggling to meet deadlines and develop a high-quality product yet keep costs down. This places them at risk of having dissatisfied customers and losing repeat business.

In this blog, we’d like to talk about the major benefits of Electronic Contract Manufacturers (ECMs) for your company.

Design to Completion

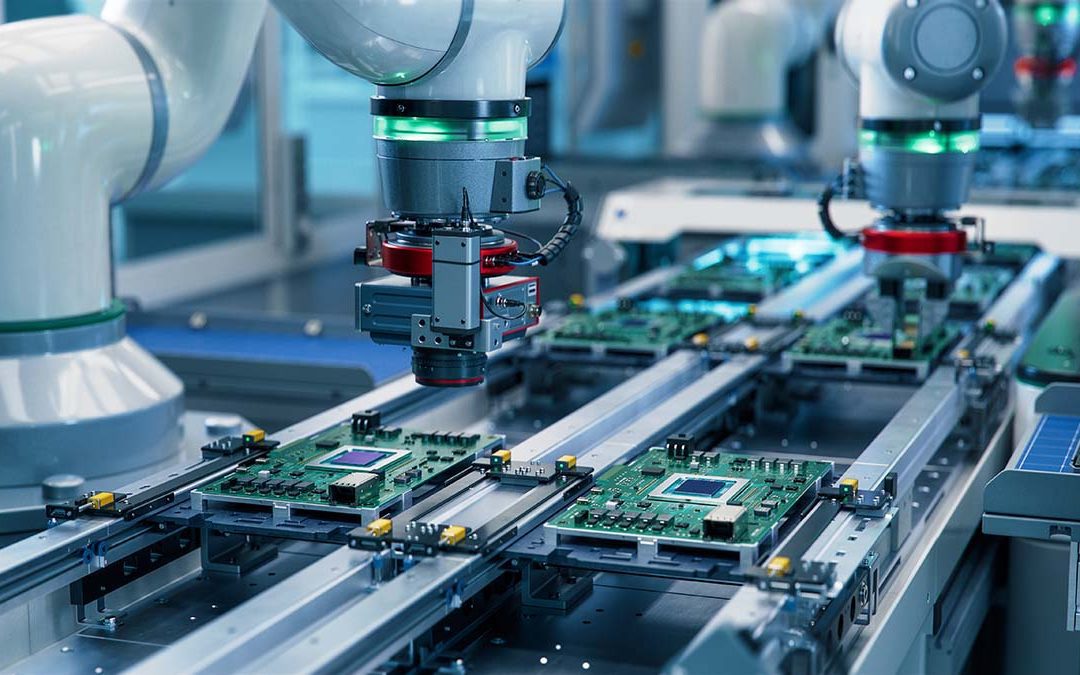

A good ECM will work with you toward designing and producing a better product. From concept to design, to prototype, to testing and improvements, you’ll be able to streamline your engineers’ ideas from start to finish and guarantee a high-quality product.

It’s all about collaboration—working with the right ECM expands your staff and capabilities. The engineering expertise of the ECM, combined with that of your in-house team, will result in an ongoing collaboration toward innovation and a better product.

You can contract almost all types of services including assembly, CNC machining, aluminum die casting, grinding, and more. Most ECMs will both manufacture and ship, which means getting your product to market sooner.

Many companies are seeing the advantages. According to a report by Grand View Research, “The global electronic contract manufacturing and design services market size was valued at USD 391.4 billion in 2018 and is anticipated to expand at a CAGR of 7.9% from 2019 to 2025. Growing functionalities such as component assembly, engineering and design of printed circuit boards, sub-assembly manufacturing, and functional testing offered by contract manufacturers are expected to drive the market over the forecast period.”

MarketWatch echoes this forecast: “The global Electronic Contract Manufacturing Services market is anticipated to reach USD 554.2 billion by 2026.”

Quality Control—Better Quality and Consistency

You can rely on ECMs for strict quality control and adherence to state and federal requirements and international standards. They have the experience and expertise to produce, test, and improve products for many industries, producing a more consistent product overall.

Cost Savings

The Grand View report states that, “Market players in developing economies are offering low-cost, outsourced services to the production and designing sectors to increase their competitiveness.”

Indeed, using an ECM can save substantially on costs, which include:

- Labor and employee benefits costs

- Manufacturing equipment and supplies costs

- Savings on manufacturing costs due to ECMs’ largescale manufacturing and lower costs per head

- Lowering of production costs due to less error and re-dos

- Substantial savings on your after-sale support costs

Quick Turnaround

Because ECMs have established relationships with suppliers, they can attain the specific materials needed and start manufacturing sooner to your requirements.

Specialized Manufacturing Services

You can offer specific benefits to the industries you serve. Whether the industry you serve is medical, industrial, military, lighting, robotics, or clean tech, you’ll be able to offer specific experience and expertise in that industry. These industries require the highest quality and there is no room for error. They need always to be able to rely on consistent, dependable products for the audience they serve.

When you offer circuit board and electro-mechanical assemblies for life-saving medical devices or for military navigations systems and robotics surveillance, your customers expect the best product available because people’s lives are depending on it.

Companies are turning to electronic contract manufacturing services because of these expectations and the pressures of increased competition, increasing costs, the complex design of electronic products, and shorter product lifecycles.

MarketWatch confirms that “OEMs (Original Equipment Manufacturers) are seeking support from electronic contract manufacturing companies. These OEMs subcontract electronic manufacturing contract companies to take advantage from their design expertise, supply chain management, and manufacturing capabilities. This helps the OEMs to leverage resources, reduce costs, access prominent manufacturing technologies, as well as reduce fixed capital investments and fulfil the electronic contract manufacturing services market demand.”

ECMs provide a high level of quality and dependability based on their years of expertise and experience in a particular industry.

Reshoring/Made in USA

An often-overlooked advantage of ECMs is the ability to keep your manufacturing in the U.S., where the transportation costs are lower and the quality is higher. Even manufacturing costs overseas are higher than they once were due to cost-of-living increases.

From a public relations point of view, employing more Americans is always good for the economy—and your image—and is likely to generate American customers who like the “Made in America” label.

Working with a qualified contract electronic manufacturing partner provides a myriad of benefits to your organization. If you’d like to explore some of these advantages, then contact us at Distron. We’ll be happy to show you exactly how we work with our electronic manufacturing clients that ensures mutually beneficial outcomes.

Recent Comments