Surface Mount & Printed Circuit Board Assembly

Electromechanical Assemblies

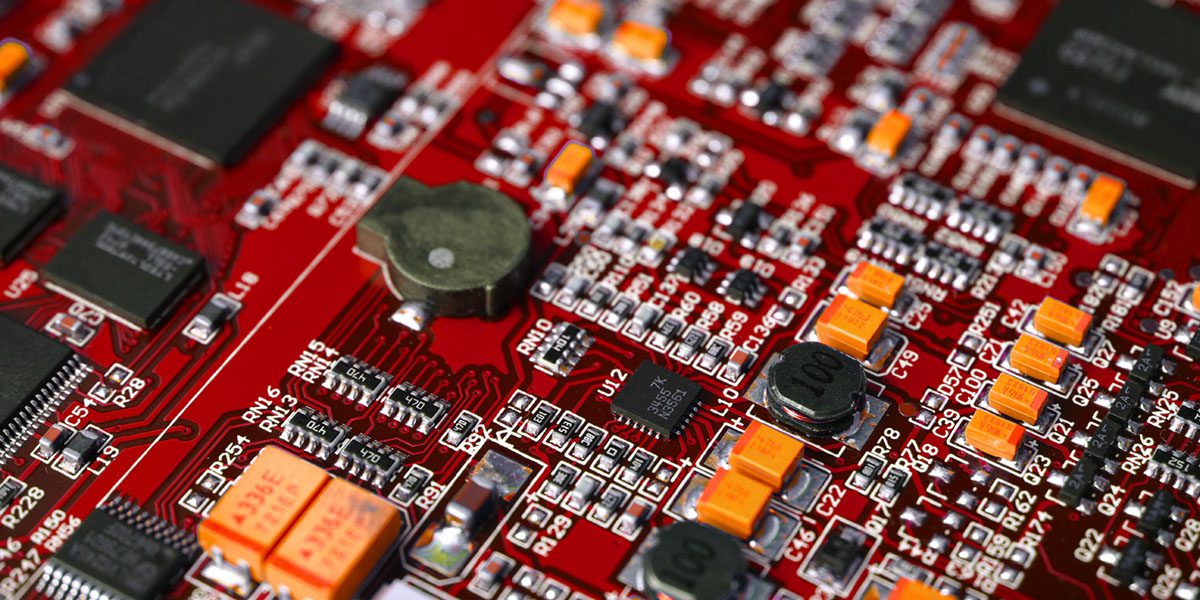

Printed Circuit Board Assemblies

When it comes to surface mount assemblies, as well as printed circuit board assemblies, Distron ensures reliability, success, and flexibility. Our dedicated surface mount assembly area is state of the art, environmentally controlled, and has four Mydata SMT assembly lines to ensure the best performance and dependability, as we manufacture all types of high-mix production at low to medium volumes. The work center is manned by highly trained personnel, fully ESD compliant, and allows for quick setup and changeover times that can easily be reconfigured whenever production requirements change. Combining reliability, experience, and adaptability is a combination that Distron prides itself on.

Distron’s Aglis feeder system enables loading and unloading of feeders in seconds, thereby maximizing productivity. We can handle placement of component spectrum from 01005 to micro BGAs. We have in-house Dage X-ray equipment for BGA repair and inspection, as well as 100 percent visual verification of all passive components. Our Aegis CAM software suite ensures detailed quality reports and traceable results, as well as lowering the cost while upping the quality. Between full in-line SMT equipment, and screen printing through automated optical inspection, we are able to not only deliver exceptional accuracy, but just as exceptional repeatability.

When it comes to circuit board assembly, our four high-speed SMT lines are equipped with screen printing, solder paste inspection, as well as component placement and 3D automated optical inspection. This enables rapid setup, with easy configuration adjustments whenever new production requirements roll out, while ensuring perfect accuracy. Distron also offers quick turn builds—not just on circuit board assembly, but on every product we work on. This is available through our New Product Introduction (NPI) services, and through our ability to do rapid prototyping of printed circuit assemblies, we are able to meet the needs of every customer in a timely, efficient manner.

Our Aegis CAM software suite also improves quality, lowers costs, and provides advanced support for quality reporting, as well as traceability. Productivity is improved via Mycronic’s advanced technology assembly platform, as feeders can be loaded in seconds. When you also take into account our innovative rework and repair equipment, our in-house X-ray capabilities for BGA repair and inspection, as well as the fact that we offer 100 percent visual verification of all passive components, it becomes easy to see why companies have come back to us, year after year, as their one-stop manufacturing partner.

Our goal is to help you meet your goals. Our qualifications make it possible.