New Product Introduction (NPI)

Realize Your Vision More Quickly

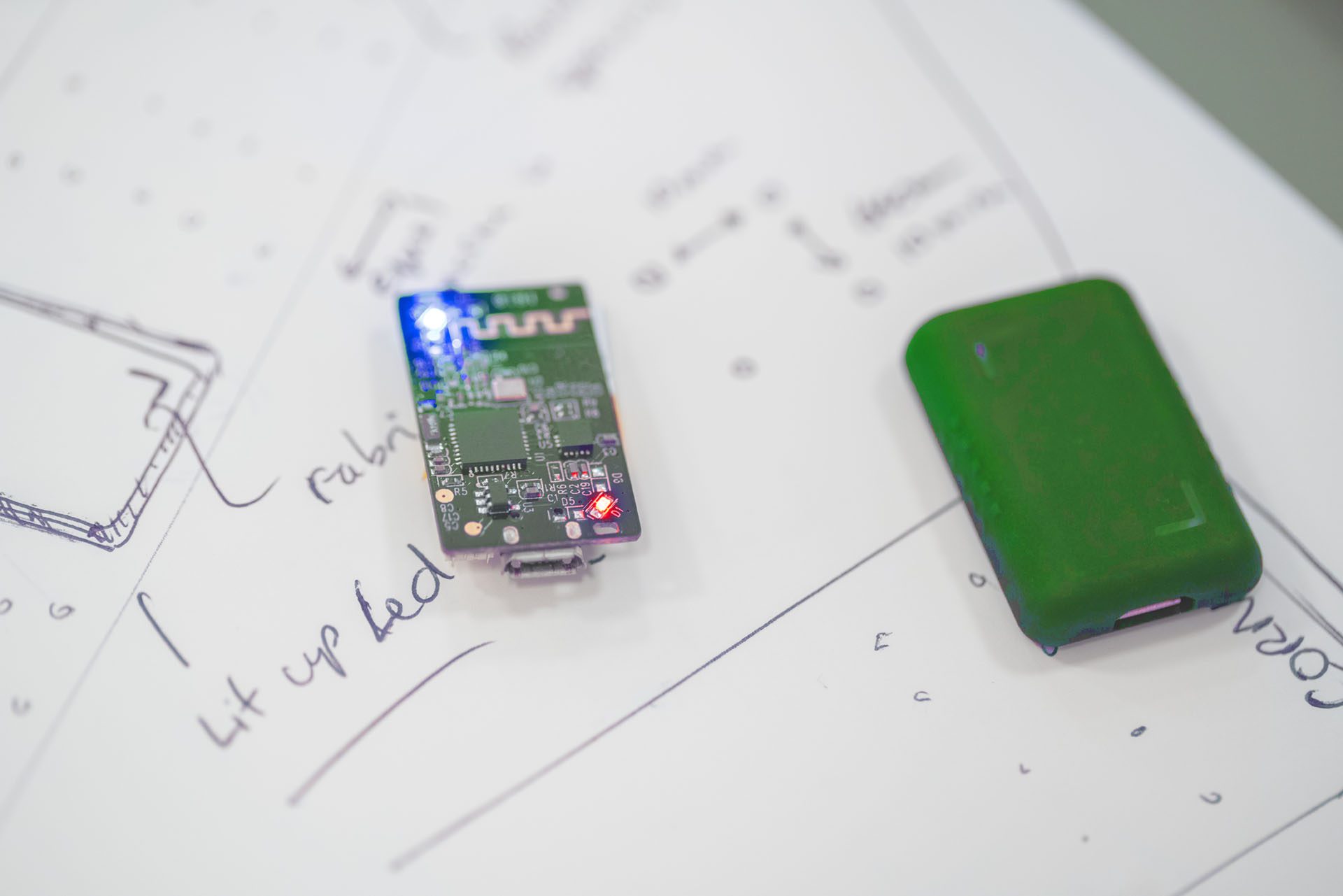

When we talk about partnering with our customers, our new product introduction (NPI) service exemplifies this.

We understand that a design needs to be validated first—and, perhaps more importantly, that your first attempt may not be your last. Multiple runs may be needed to resolve issues at the New Product Introduction (NPI) stage. A tangible build is necessary to analyze the production both the production method and the finished product. However, we also understand that time is usually critical.

We can deliver a New Product Introduction (NPI) within an expedited time frame. Our Mycronic SMT lines work well with smaller lots and frequent changes associated with NPI production.

Our goal is to help you meet your goals. Our qualifications make it possible.

Put our experience to work for you.

ECM Case Study

An Original Equipment Manufacturer (OEM) of ruggedized military power modules, Needed to outsource production in order to create floor space for a new product line. At the same time, they wanted to retain the manufacturing standards that enabled them to pass MIL-STD-810G testing.

Additionally, they needed to find a contract manufacturer that already employed exacting quality standards, cutting-edge equipment and capabilities, and world-class supply-chain practices. The OEM turned to Distron.