Selecting the right conformal coating process is one of the most important decisions you can make for your electronic assemblies. The right approach delivers consistent protection, long-term reliability, and confidence in every unit shipped. The wrong one can introduce variability, extended lead times, and performance risks in the field.

At DISTRON, we combine more than 50 years of manufacturing experience with advanced automation to deliver high-quality, repeatable conformal coating solutions. Our customers rely on us to protect their products with precision, consistency, and control especially in environments where failure is not an option.

What to Look for in a Conformal Coating Process

Choosing a coating solution is about more than applying material. It’s about accuracy, repeatability, and control throughout the entire process. A high-quality conformal coating operation should demonstrate:

- Automated Application that minimizes human variability

- Precision Placement to protect components without overcoating

- Controlled Curing Methods matched precisely to coating materials

- Scalable Throughput to support growing production demands

- Process Visibility that ensures consistent, repeatable results

Why It Matters

Conformal coating is often the last line of defense for an electronic assembly. Manual masking and hand-applied coatings can introduce inconsistency, extend cycle times, and increase the risk of defects especially as designs become denser and tolerances tighten.

In regulated and high-reliability industries, inconsistent coating can lead to premature failures, costly rework, and reduced product lifespan. Automation reduces those risks by ensuring every board is coated and cured correctly, every time.

How DISTRON Helps You Succeed

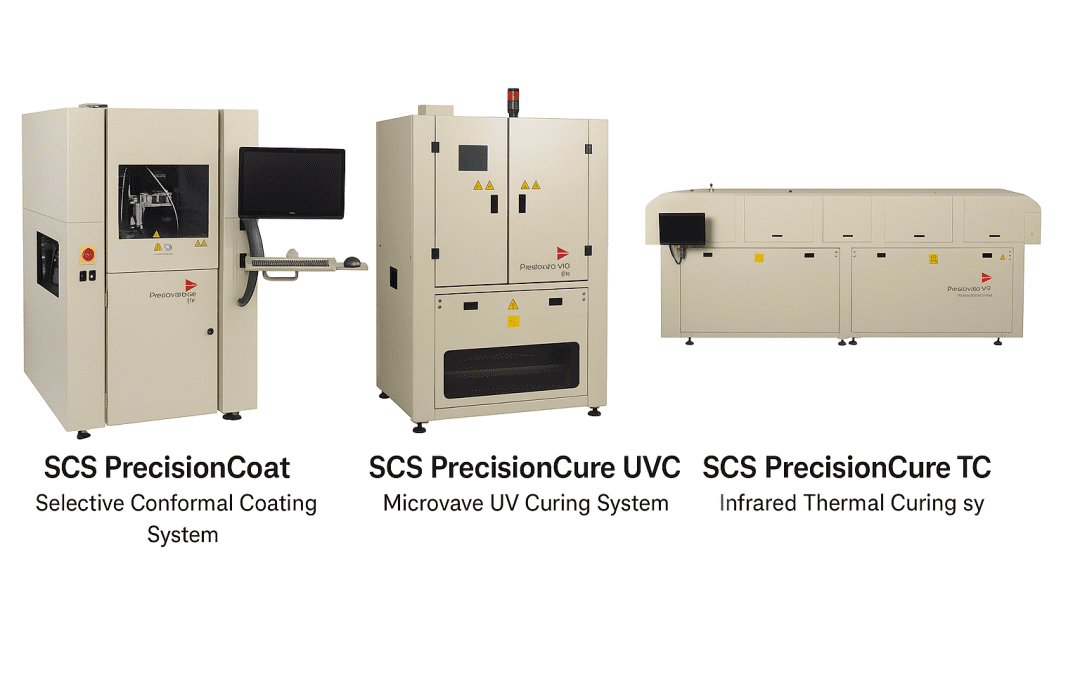

To elevate coating quality and efficiency, DISTRON has invested in a fully automated conformal coating line built around three integrated technologies:

- Automated Selective Coating

Acrylic and UV coating processes that eliminate up to 99% of manual masking, improving consistency and reducing handling time - PrecisionCoat VI Platform

A fully programmable selective coating system with up to eight interchangeable coating heads for precise, repeatable application - Advanced Curing Capabilities

Integrated UV and infrared thermal curing systems that ensure proper cure profiles for a wide range of coating materials - Scalable Production

Efficient workflows that support both low-volume pilot builds and high-throughput production - Quality-Driven Execution

Coating processes designed to protect product performance in demanding environments

For more than five decades, DISTRON has served as an extension of our customers’ engineering and operations teams. Our investment in advanced coating automation reflects our commitment to protecting product integrity while improving efficiency and repeatability.

Connect with our team to learn how our advanced conformal coating capabilities can help protect your electronic assemblies and support long-term product reliability with confidence.

Recent Comments