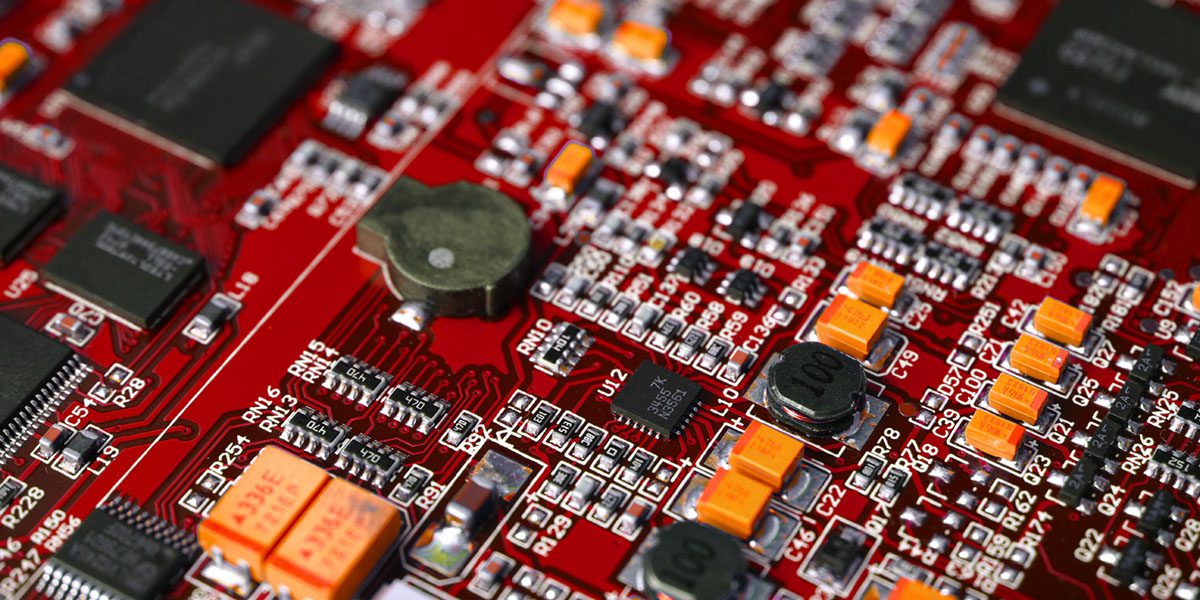

Surface Mount & Printed Circuit Board Assembly

High-Precision Circuit Board Assembly Services

When it comes to surface mount technology (SMT) and circuit board assembly, Distron delivers unmatched reliability, flexibility, and precision. As a trusted provider of contract electronics manufacturing services, we specialize in building robust PCB assemblies that meet demanding industry standards. Our dedicated SMT facility is state-of-the-art, environmentally controlled, and equipped with four Mycronic SMT assembly lines to ensure high-speed, repeatable, and accurate circuit board assembly. We support high-mix, low-to-medium volume production, making us ideal for emerging technologies and specialized industries such as medical device manufacturing, defense electronics, and industrial electronics manufacturing. Our work center is fully ESD-compliant and designed for rapid setup and changeovers—perfect for evolving needs and flexible manufacturing solutions. Our combination of reliability, technical experience, and adaptability makes Distron a trusted partner in the electronics manufacturing industry.

Our Agilis feeder system enables lightning-fast component swaps, maximizing uptime and throughput. We handle component placement ranging from 01005 chips to micro BGAs. Our in-house Dage X-ray supports inspection and testing services, including BGA inspection and rework, and we provide 100% visual verification of all passive components to ensure build integrity. Using Aegis FactoryLogix, we provide full build traceability, quality reporting, and process validation—key features for regulated markets and high-reliability builds. Our fully in-line SMT equipment includes solder paste inspection (SPI), screen printing, high-speed pick-and-place, and 3D automated optical inspection (AOI)—delivering exceptional accuracy and consistency across every build.

Our SMT lines support rapid prototyping services, prototype PCB assembly, and full production, all while maintaining the tight tolerances required by advanced electronic systems. This agile setup supports rapid production and quick-turn changes—vital for New Product Introduction (NPI), revisions, and iterative development cycles. Our quick-turn capabilities are not limited to circuit board builds. We also support through-hole PCB assembly, cable and harness assembly, and electromechanical assembly, offering a complete solution under one roof. From NPI to pilot builds to full-scale production, our rapid prototyping and assembly services help you bring products to market with speed and confidence.

With Mycronic’s advanced assembly platform, we reduce downtime and increase throughput by enabling feeder reloads in seconds. From in-house BGA X-ray inspection and rework to visual inspection and process control, Distron ensures every board meets the highest quality standards—another reason we’re a preferred partner in contract electronics manufacturing.

Let our experience in circuit board assembly and inspection and testing services help bring your product to life—with speed, precision, and accountability.