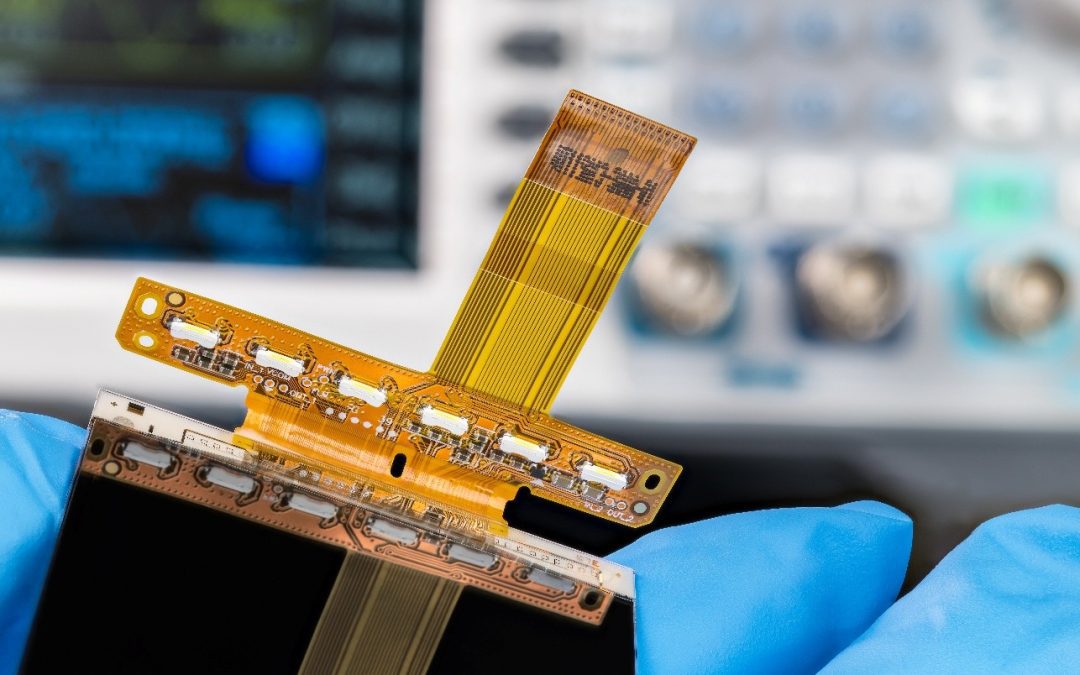

Space, weight, and design constraints are pushing OEMs to rethink their PCB strategies — and flexible circuit assemblies are emerging as a powerful solution. In 2025, flex and rigid-flex PCBs are gaining traction across industries, from wearable healthcare to aerospace and industrial automation.

At DISTRON, we’ve helped multiple OEMs transition to flex successfully — delivering both performance and reliability without compromise.

What’s Driving the Shift:

- Demand for smaller, lighter, and more dynamic products

- Need to reduce part counts and improve system integration

- Desire to eliminate bulky connectors and increase design flexibility

- Greater reliability due to fewer interconnects and solder joints

Where Flex is Taking Hold:

- Medical: Wearables, portable monitors, diagnostic tools

- Aerospace & Defense: Space-optimized, rugged electronics

- Consumer Tech: Foldable devices, IoT, and smart wearables

- Robotics & Automation: Systems with frequent motion or vibration

Why DISTRON is the Right Partner for Flex:

- Proven expertise in multilayer flex and rigid-flex assembly

- Custom tooling and fixturing for precision during production

- Testing protocols designed to simulate real-world stress

- End-to-end manufacturing support from prototyping to final test

As flex technologies become more mainstream, it’s critical to partner with a manufacturer that understands the intricacies of these designs. DISTRON brings technical know-how, certified processes, and hands-on support to every flex build.

Recent Comments