<

<

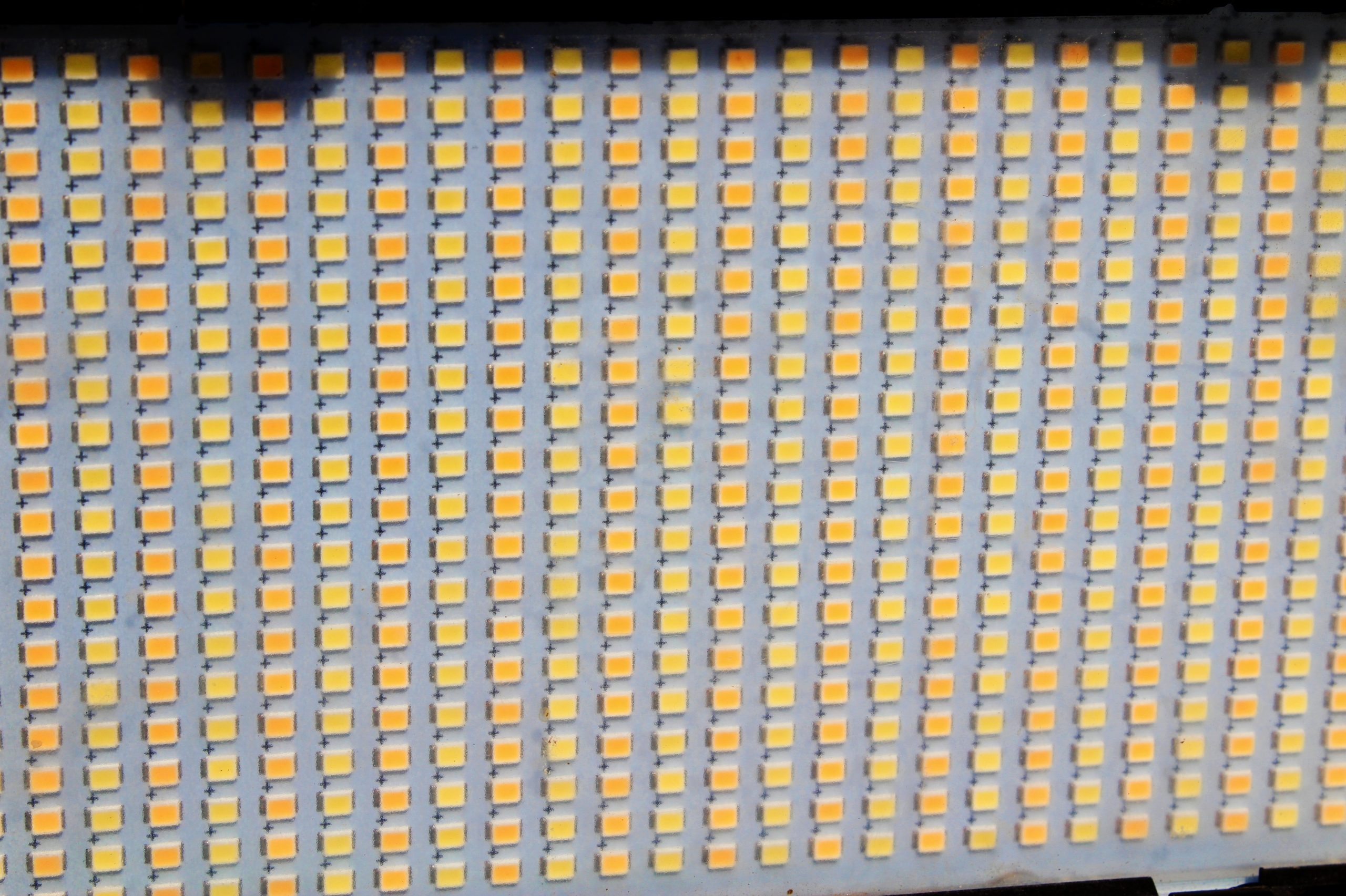

Case Study: Delivering Scalable, High-Quality LED Lighting Solutions Through Agile Electronic Manufacturing

THE CHALLENGE

A U.S.-based OEM specializing in smart commercial and architectural LED lighting was preparing to launch a next-generation product family targeting office buildings, public infrastructure, and government projects. The timeline was aggressive, and the stakes were high. The company needed to fast-track its new product introduction (NPI) while incorporating the latest LED innovations and integrated controls. Past delays and inconsistent quality from overseas EMS partners had led them to prioritize a domestic manufacturing partner. With complex bills of materials (BOMs) that were evolving rapidly and stringent UL and energy-efficiency certifications to meet, the OEM needed a nimble, collaborative EMS partner that could ensure consistent binning, brightness, and color temperature: crucial requirements for architectural applications.

THE DISTRON SOLUTION

To meet the customer’s complex requirements and fast-track its product launch, DISTRON CORPORATION delivered a comprehensive, U.S.-based manufacturing solution tailored to the unique needs of LED lighting production:

-

- Vendor Managed Inventory (VMI): Enabled rapid responsiveness with vendor-owned stock to support fluctuating demand

- Automated LED Binning: Delivered precise brightness and color performance through custom binning automation

- Design Review/DFM Collaboration: Provided early-stage design feedback to improve manufacturability and reduce costs

- Lean Manufacturing Cell: Established a dedicated build-to-order cell to maximize efficiency and scalability

- Custom Functional Test Sets: Developed in-house fixtures to validate thermal, brightness, and reliability metrics

- Environmentally Friendly Packaging: Created reusable, protective packaging tailored to the product’s fragility and size

- Value-Add Services: Offered final assembly, firmware loading, and conformal coating all under one roof

THE RESULTS

DISTRON’s agile, end-to-end support enabled the lighting OEM to reduce production lead times by 30% and cut field failure rates by 40% — a direct result of precise LED binning and rigorous in-house testing. The customer successfully scaled from prototype runs to 20,000 units per year in less than six months, a critical milestone that aligned with its market launch. With DISTRON’s help, the company also achieved UL certification in record time and qualified for several smart city energy-efficiency grant programs. As a result of the smooth launch, consistent product quality, and on-time delivery, the OEM secured three high-profile municipal lighting contracts shortly after release.

Ready to Achieve Results Like These?

At DISTRON, we turn complex manufacturing challenges into streamlined, high-quality solutions that accelerate your product’s success. Whether you’re launching a new line, optimizing for cost-efficiency, or enhancing product reliability, we’re here to support your vision with proven expertise.

Let’s discuss how we can bring your project to life.

Contact Us Today to explore a tailored manufacturing solution for your next product.

Or, Download Our Capabilities Guide to see how we drive results in various industries, from LED lighting to advanced electronics.