Inspecting and Testing

Advanced Inspection and Testing Services for Electronics Manufacturing

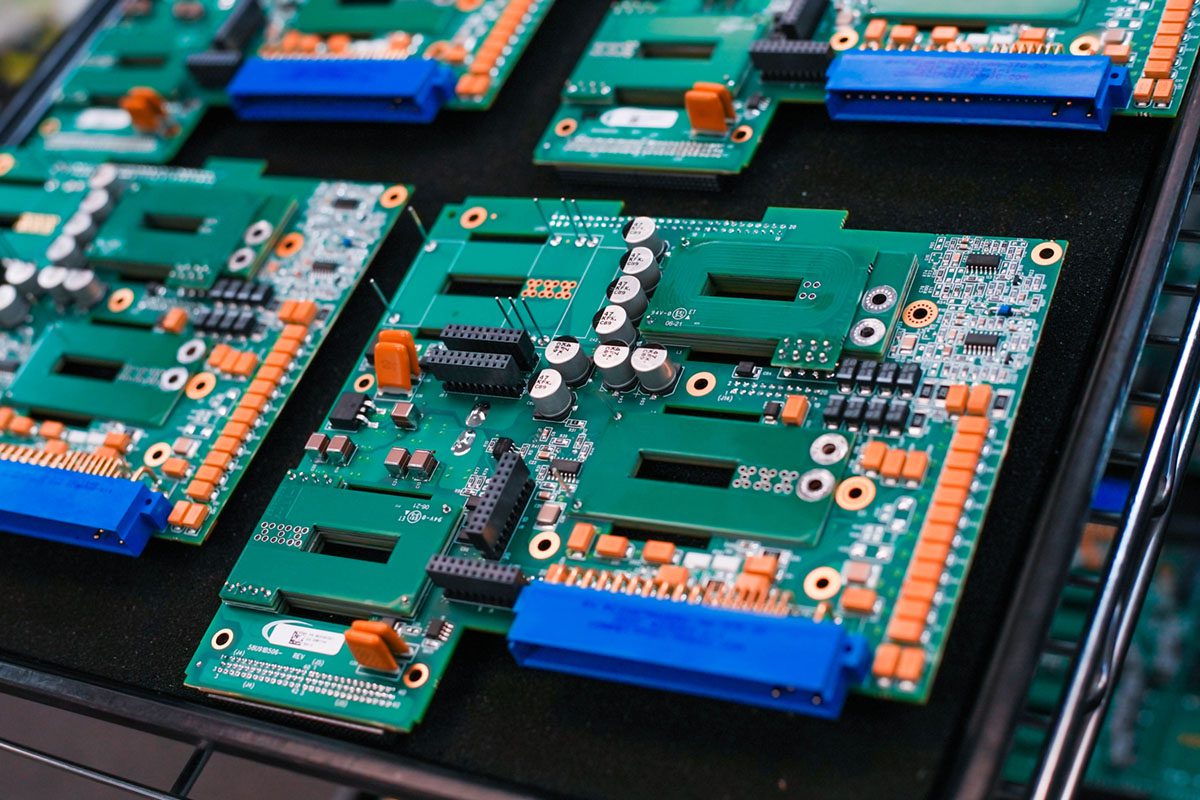

In electronics manufacturing, few elements are as critical as quality assurance. That’s why Distron’s inspection and testing services are built into every stage of production—covering incoming materials, in-process checks, and final inspection. Our IPC-A-610 certified operators and advanced Automated Optical Inspection (AOI) systems ensure consistent quality across every build, from prototype PCB assembly to full production runs.

We utilize in-line Solder Paste Inspection (SPI) systems to verify solder quality early in the process, reducing downstream defects. Our SMT platforms include visual verification tools and AOI systems that confirm component placement accuracy, polarity, solder quality, and part presence—ensuring consistent results across both small and large batch builds. These systems are essential to our flexible manufacturing solutions, enabling fast changeovers without compromising quality.

To support both NPI (new product introduction) services and long-term production, Distron uses advanced test platforms such as the Seica Flying Probe system—a fixtureless, cost-effective solution that supports fast deployment and quick design changes. Our Dage BGA X-ray Inspection system provides non-destructive validation to detect shorts, opens, and hidden defects under BGA and QFN packages. For high-reliability sectors like medical device manufacturing and defense electronics, our standalone thermal chambers and burn-in rooms simulate environmental stress and validate long-term performance.

For customers with unique verification needs, we offer custom test development—ranging from firmware validation to functional and in-circuit testing. Whether you’re building mission-critical assemblies or short-run prototypes, Distron’s inspection and testing services ensure your electronics meet the highest performance and compliance standards. It’s just one more way we deliver excellence as part of our contract electronics manufacturing offerings.