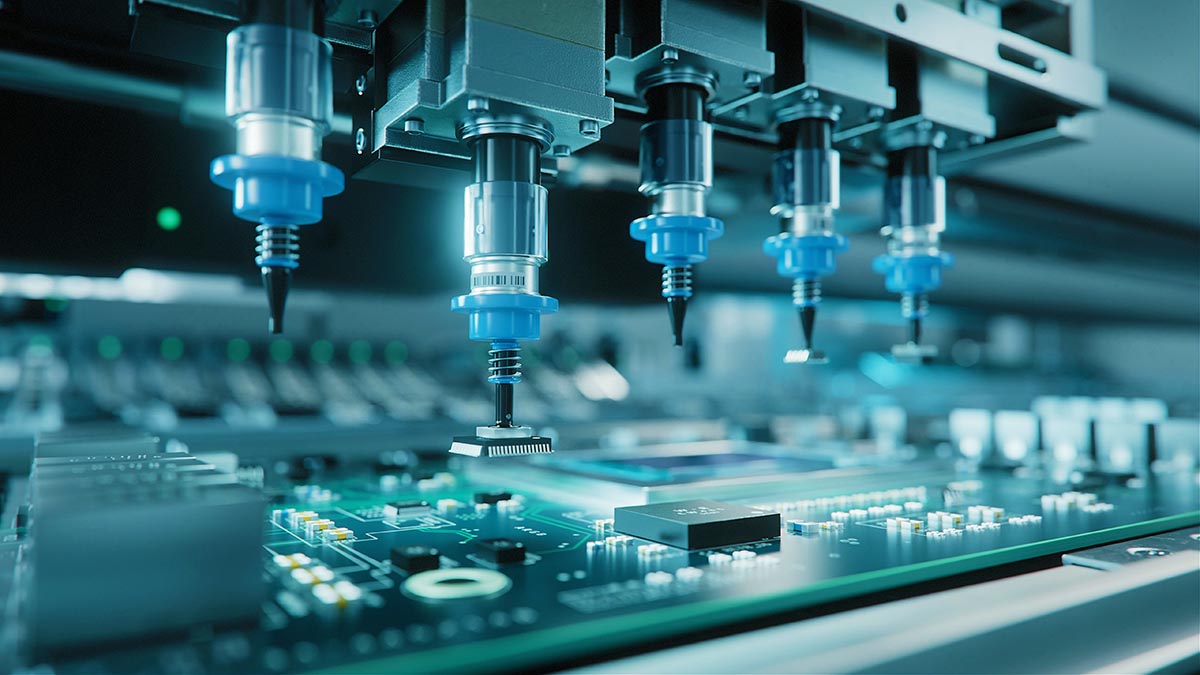

The COVID-19 pandemic has had a significant impact on manufacturing, especially electronic contract manufacturing, affecting everything from supply chains to production processes. As the world continues to grapple with the aftermath of the pandemic, the electronic manufacturing industry is also adapting to new realities and changes.

Supply chain disruptions in ECM

One of the biggest challenges that electronic contract manufacturers have faced during the pandemic is supply chain disruptions. With lockdowns and travel restrictions in place, many manufacturers were unable to source raw materials and components from overseas, leading to delays and production shortages. As a result, many manufacturers have been forced to find new suppliers and diversify their supply chains to ensure continuity of production. Even still most experts don’t expect the supply chain issues to completely resolve until the latter half of 2024.

Remote work & automation

The pandemic has also accelerated the adoption of remote work and automation in manufacturing. With many employees unable to work on-site due to lockdowns and social distancing measures, manufacturers have had to find ways to keep production going remotely. This has led to increased use of digital tools and automation to remotely monitor and control production processes.

Increased focus on safety

The pandemic has also led to an increased focus on safety in manufacturing. With the threat of COVID-19, manufacturers have had to implement new measures to protect workers and prevent the spread of the virus. This includes things like temperature checks, mask requirements, and increased cleaning and sanitation.

Changes in consumer demand

The pandemic has also led to changes in consumer demand. With many people staying at home, there has been an increase in demand for certain products such as home office equipment and home workout equipment, while demand for other products such as travel-related items and luxury goods has decreased.

Reshoring electronic contract manufacturing

The pandemic has also led to a resurgence of reshoring, or the process of bringing manufacturing back to United States factories. With supply chain disruptions and uncertainty caused by the pandemic, many manufacturers are looking to bring production closer to home to reduce their dependence on overseas suppliers–something Distron wholeheartedly supports.

The COVID-19 pandemic has fundamentally changed the manufacturing process. Luckily, Distron stays ahead of the curve and has the flexibility to adapt without losing pace with market demands. If you need a electronics contract manufacturer who will truly partner with your process and has the ability and expertise to adapt to this new environment, then we’d love for you to contact us.

Recent Comments